Add to Cart

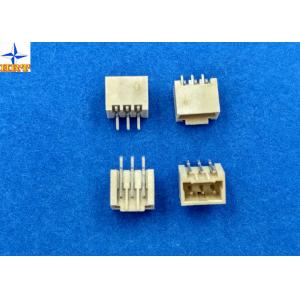

Wafer Connector Pitch 1.50mm Pin Brass/ Tin-plated wire to board connectors

Description:

1.A1501 series Wafer have A1501WV A1501WR (Single row housing suitable A11501-T series terminal )

2, Wafer used materials:PA6T , Fire-protection rating is UL 94-V0. Minimum packing quantity is 1000pcs/bag.

3. Single row Wafer we have 02PIN~15PIN ,The daily production capacity is 30 to 50 KPCS.

4.Terminals are stamped by Phosphor Bronze, E-Stamping beforeTin-plated , Tin-plated we calling A1501-TPe , Minimum packing quantity is 20,000pcs/Reel. The daily production capacity is 300 to 400 KPCS.

5.Terminals' wire range :AWG #22--#28insulation OD is0.90mm(Max).

| Test Description | Procedure | Requirement |

|

Contact Resistance |

Mate connectors, measure by dry circuit, 20mV max., 10mA.(Based upon JIS C5402 5.4) | 20mΩ (Max.) |

| Insulation Resistance | Mate connectors, apply 500V DC between adjacent terminal or ground. (Based upon JIS C5402 5.2/MIL-STD-202 Method 302 Cond. B) | 1000MΩ (Min.) |

| Dielectric Withstanding Voltage | Mate connectors, apply 800V AC (rms) for 1 minute between adjacent terminal or ground. (Based upon JIS C5402 5.1/MIL-STD-202 Method 301)) | No Breakdown. |

| Contact Resistance on Crimped Portion | Crimp the applicable wire on to the terminal, measure by dry circuit, 20mV (Max.)., 10mA. | 5mΩ (Max.) |

| Current rated | 3A AC/DC maximum |

| Voltage rated | 350V AC/DC |

| Withstand voltage | 500V AC/minute |

| Insulation resistance | 1000MΩ min |

| Contact resistance | 20MΩ max |

| Operating temperature | -25 - 85°C |

Environmental Performance And Others

| Test Description | Procedure | Requirement | |

| 6-1 | Temperature Rise | Carrying rated current load.(Based upon UL 498) | 30℃(Max.) |

| 6-2 | Heat Resistance | 85±2℃,96 hours (Based upon JIS C0021/MIL-STD-202 Method 108A Cond. A) |

Appearance No Damage. Contact Resistance 40mΩ (Max.) |

| 6-3 | Cold Resistance | -25±3℃,96 hours (Based upon JIS C0020) | |

| 6-4 | Humidity |

Temperature: 40±2℃ Relative Humidity : 90~95% Duration: 96 hours (Based upon JIS C0022/MIL-STD-202 Method 103B Cond. B) |

Appearance No Damage. Contact Resistance 40mΩ (Max.) Insulation Resistance 100MΩ (Min.) Dielectric Withstanding Voltage Must meet 4-3 |

| 6-5 | Temperature Cycling |

5 cycles of: a) -55℃ 30 minutes b) +85℃ 30 minutes (Based upon JIS C0025) |

Appearance No Damage. Contact Resistance 40mΩ (Max.) |

| 6-6 | Salt Spray | Tin-plated 12 hours / Gold- plated 24 hours exposure to a salt spray from the 5±1% solution at 35±2℃. (Based upon JIS C0023/MIL-STD-202 Method 101C Cond. B) | |

| 6-7 | SO2 Gas |

24 hours exposure to 50±5ppm. SO2 gas at 40±2℃. |

|

| 6-8 | NH3 Gas | 40 minutes exposure to NH3 gas evaporating from 28% Ammonia solution. | |

| 6-9 | Solderability |

Soldering Time: 5±0.5 sec. Solder Temperature: 245±5℃ |

Solder Wetting 95% of immersed area must show no voids, pin holes |

| 6-10 | Resistance to Soldering Heat |

Solder pot method Soldering time: 10±0.5 sec. Solder Temperature: 260±5℃ Solder iron method Soldering Time: 5±0.5 sec. Solder Temperature: 370℃ ~ 400℃ |

Appearance No Damage. |

Actuator Insertion/Withdrawal Force

[Unit : kgf]

| Circuits | At Initial | |

| Insertion (Max.) | Withdrawal (Min.) | |

| Single | 0.70 | 0.06 |

| 02 | 2.50 | 0.30 |

| 03 | 3.00 | 0.40 |

| 04 | 3.50 | 0.50 |

| 05 | 4.00 | 0.60 |

| 06 | 4.50 | 0.70 |

| 07 | 5.00 | 0.80 |

| 08 | 5.50 | 0.90 |

| 09 | 5.50 | 1.00 |

| 10 | 6.00 | 1.10 |

| 11 | 6.00 | 1.20 |

| 12 | 6.50 | 1.30 |

| 13 | 6.50 | 1.40 |

| 14 | 7.00 | 1.50 |

| 15 | 7.00 | 1.60 |